SEPTOMAX® // Applications

internal/invisible Hinges & Kinematic Concepts for sector-independent use

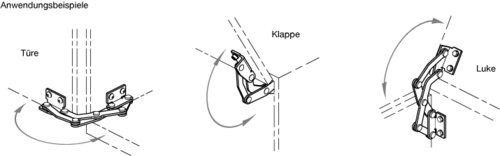

The „application radius“ of SEPTOMAX products is as wide as its kinematic design variability. There is not a specific market nor a reduction to a certain mounting way for this multi link principle so the application options are actually unlimited; for the standard and even the customized versions. For that reason SEPTOMAX solutions are internationally used across industries, in medium sized businesses and from craftsmanship.

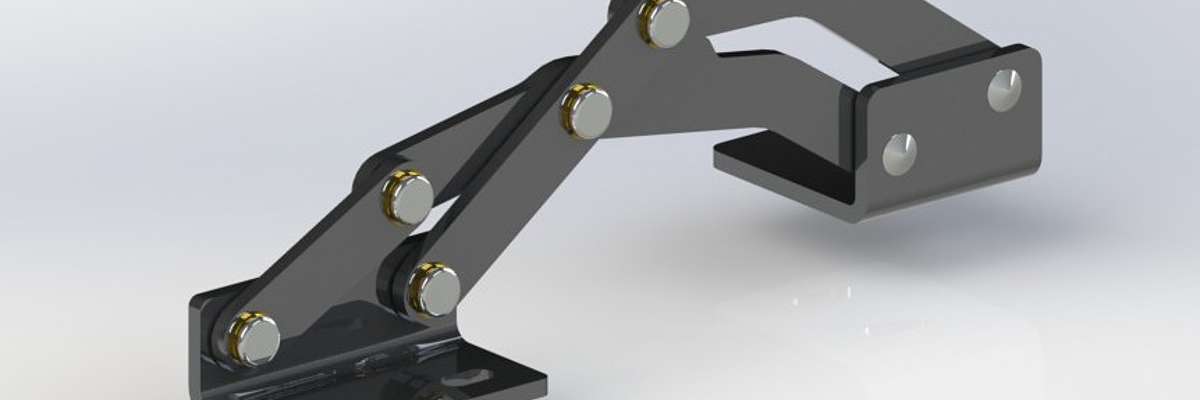

Beyond its use as hinge product many customers integrate the SEPTOMAX idea as hinge-independent kinematic-sequence for example to move goods from one point to another or to lift up tables, windows or loose parts. SEPTOMAX from that point of view is more a functional principle that can used for any linear, non linear or customized sequence to connect a moving part to a fixed one with a defined kinematic.

To demonstrate the wide variety of using options please follow our below mentioned categories:

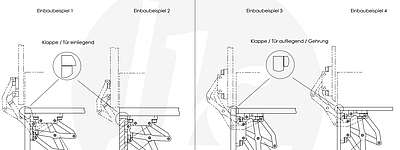

- Applications... by Mounting and on-lying // How can SEPTOMAX goods be assembled?

- Applications... by Industry // Who use the Septomax solution?

- Applications... by Design // What design options are realizable?

- Applications... by Technique // What are the technical conditions?

- Applications... by Function // What „hinge-independent“ usages are possible?

Applications // by Markets & Sectors

One of the core competences of the SEPTOMAX range is it´s market independent character. A hinge solution for contemporary demands that offers maximum freedom in design and construction of hatches, doors or flaps; for any given industry or assembling case. Without any restriction in quantity or kinematic requirement. Usable for industrial customers, handcraft businesses and even design related users. Some of the SEPTOMAX target markets...

Industry // Bus / Rail / Automotive / Cab / Medical / Traffic Engineering / Mechanical Engineering / Shipbuilding / Agricultural machinery / Advertising technology / Construction machines / Sports and leisure equipment / Mobile homes / Polymer technology / Electrical industry / Container construction / Packaging technology / Plant construction / Light engineering / Logistics systems and many more.

Small & Handcraft Businesses // Woodworking, metalworking, architects, furniture / kitchen construction, showcases, door / gate construction, trade fair / shop building, drywalling, gardening / landscaping, fence systems, climatic engineering, interior design, window construction, sauna systems, glass applications

Traders & Engineering // (CAD) planning & Construction companies, specialist / wholesale trader, construction planning, standard part trade

(directly to the Product overview...)

// Selected Applications & Markets:

Application // by Design

For furniture, vitrines or specific design-oriented applications

Optical features are key selling factors for many different applications; especially design related markets require „clean“ surfaces“ as a standard element. That´s why we develop our SEPTOMAX products even under the keyword „industrial design“. We are interested in the visual demands of engineers and designers who are responsible for the optical effect of their final products. The fact that „form & function“ are two sides of one medal shows the need to integrate these aspects in our construction process; that´s why we focus on six elements...

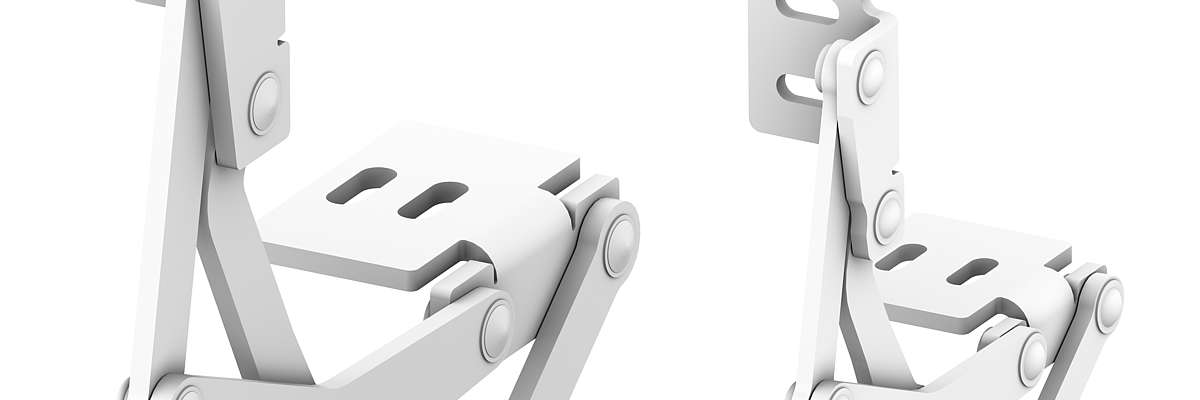

- Assembling // Free choice of on-laying ways from overlapping, to enclosed and mitred

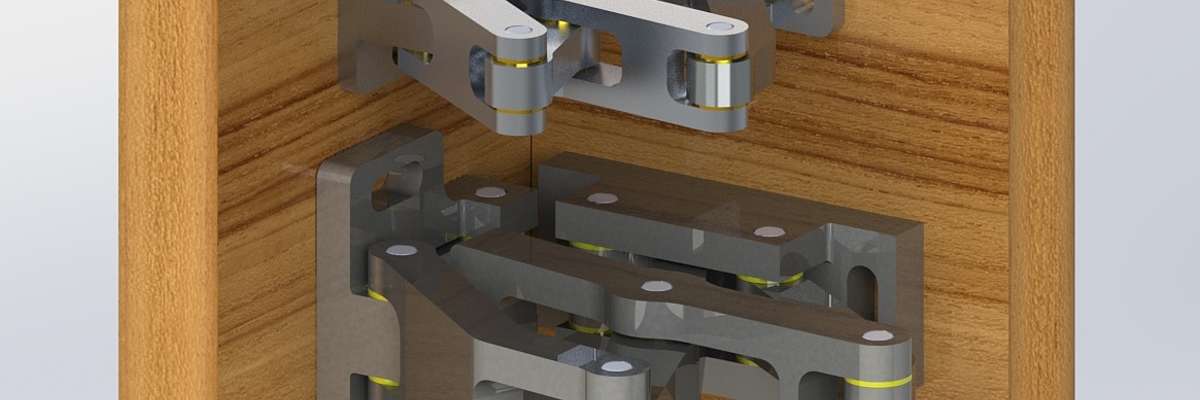

- Field of view // Internal mounting offers a fully „cleaned“ surface without any hinge-related restriction

- Surface // Different types of surface treatments usable from powder coating and galvanization to chromatized and anodized surfaces.

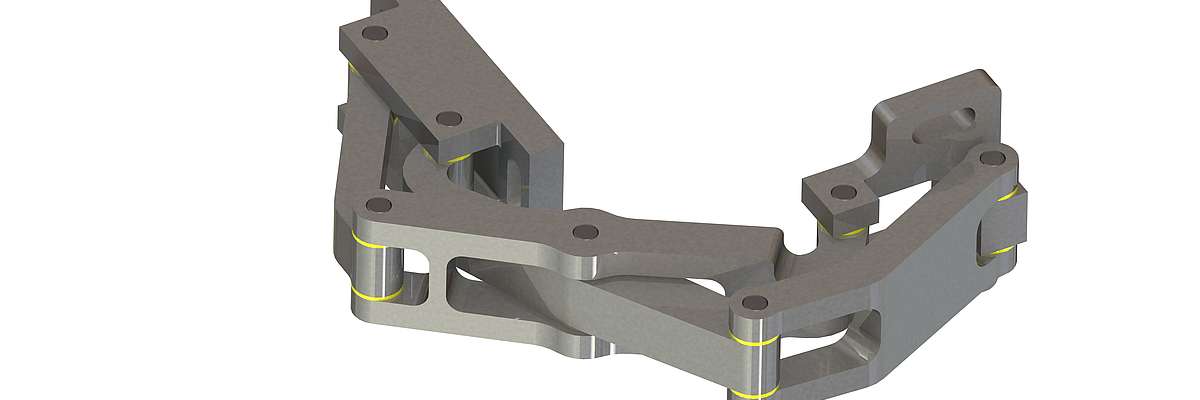

- Material // High value materials from stainless steel to alloy and 3D-models

- Function // Maintenance free parts for silent opening sequences and add on parts such as gas springs etc.

- Construction // Customized kinematics for an individual design of final products, small assembling spaces or any specific underlying material (wood, glass, metal, polymer etc.)

Examples of our design-related target groups:

Architects, Designer, Glass manufacturer, vitrine and furniture builders, Kitchen manufacturing, carpenters, engineering offices, Museum equipment, Store-fronts & Facades, Displays & Exhibition stands, Advertising technique etc. (product overview)

Application // by technical Parameters

The potential of SEPTOMAX products to be widely useable in many different applications and markets is one of it´s main competences; but it even highlights that a few aspects need to be considered to guarantee the full technical effect of such a complex hinge solution.

The proper usage and mounting of Septomax products is mainly depending on the following central parameters:

- SEPTOMAX hinges are complex kinematics based on multi pivot technology. That means that central parameters such as opening angle, weight load or door thickness for example do interact with each other. In a certain case an increase of door thickness leads to smaller opening angles for example. That means that the individual mounting situation defines the possible usage and design options of multi link solutions.

- Therefore the more technical date of one assembling case we receive the more focused we can design and offer a proper SEPTOMAX version. Taking all the economic and technical informations into account is vital before setting up a construction process.

- To avoid any damages or wrong usages we recommand our Assembling Advices for SEPTOMAX products.

Application ... by Mounting // ... by Industry // ... by Design // ... by Technique // ... by Function